Daikin

Contents

Setting Indoor Group Address

Indoor Group Address is required for proper CoolMasterNet operation. Without Group Address Indoor unit is not visible and can not be controlled by CoolMasterNet. Group Address is set with wired remote controller. Here is a simple sequence of operations for Daikin BRCE61 wired remote controller to set Group Address.

- Press and hold Cancel button for a few seconds

- Scroll down to Group No. setting function and press Menu/Enter button

- Program Group Address and then press Menu/Enter to save address

Remember if Indoor unit can not see a CoolMasterNet you won't have the Group Address menu option. So make sure the CoolMasterNet is wired to F1 F2 HVAC line and powered.

Reading Thermostat ambient temperature instead of return air

CoolMasterNet will read ambient temperature measured by Thermostat - local wired controller (like BRC1E72) if following field settings had being done on Thermostat:

Setting 10-2 = 03 - Only the thermostat thermistor will be utilized by Indoor unit.

Setting 10-5 = 02 - Room temperature value reported to CoolMasterNet by Indoor is taken from Thermostat

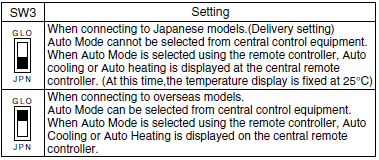

KRP928A2S Auto Mode Control

To enable proper Auto Mode control from CoolMasterNet of the Indoor Unit connected via KRP928A2S adapter, make sure to configure SW3 switch to GLO position:

Daikin Self-diagnostic Malfunction (Error) Codes

| I n d o o r U n i t |

Malfunction

Code |

Problem

Description |

Supposed

Causes |

Models | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| RA | Sky Air |

VRV | Pac kage |

HRV | Chil ler |

Fan Coil | ||||

| A0 | External protection device activated | External protection device connected to the terminal strip T1-T2 of indoor unit is activated | V | V | V | |||||

| A1 | Malfunction of indoor unit PCB | Defective indoor unit PCB External factor (Noise etc.) |

V | V | V | V | V | V | ||

| A3 | Drain Level Control System Abnormality | Drain clogging, upward slope, etc Defective drain pump Defective float switch or short circuit connector |

V | V | V | V | V | |||

| A4 | Malfunction of freezing protection | Shortage of water volume Low water temperature setting Defective water temperature thermistor |

V | V | V | V | V | V | ||

| A5 | High pressure control in heating, freeze-up protection control in cooling | Clogged air filter of indoor unit and short circuit Defect of indoor unit heat exchanger thermistor |

V | V | V | V | ||||

| A6 | Malfunction of fan motor | Broken wires in, short circuit of, or disconnection of connectors from the fan motor harness Defective fan motor Defective indoor unit PCB |

V | V | V | V | V | |||

| A7 | Malfunction of swing flap motor | Defective swing fl ap motor Defective indoor unit PCB Defective connection cable Defective airflow direction adjusting fl ap-cam |

V | V | ||||||

| A8 | Malfunction of power supply or AC input overcurrent | Defective power supply voltage Defective connection on signal line Defective wiring |

V | V | V | |||||

| A9 | Malfunction of electronic expansion valve | Defective electronic expansion valve coil Defective indoor unit PCB Defective relay cables |

V | V | V | V | V | |||

| AA | Heater overheat | 26WH is activated | V | V | ||||||

| AF | Malfunction of a humidifi er system | Humidifi er unit (optional accessory) leaking Defective drain piping (upward slope, etc.) Defective indoor unit PCB |

V | V | V | |||||

| AH | Malfunction of dust collector of air cleaner | Defect of dust collecting element Stained insulator part Defect of high voltage power supply unit Defect of indoor unit PCB |

V | V | V | V | ||||

| AJ | Malfunction of capacity setting(Indoor unit PCB) | The capacity setting adaptor was not installed when replacing PCB. Defective indoor unit PCB |

V | V | V | |||||

| С1 | Failure of transmission (between indoor unit PCB and sub PCB) | Defective connection of the connector between indoor unit PCB | V | V | ||||||

| С4 | Malfunction of liquid pipe thermistor for heat exchanger | Defective thermistor for liquid pipe Defective indoor unit PCB Defective connector contact |

V | V | V | V | V | V | V | |

| C5 | Malfunction of gas pipe thermistor for heat exchanger | Defective thermistor for gas pipe Defective indoor unit PCB Defective connector contact |

V | V | V | V | V | |||

| C6 | Malfunction of fan motor sensor or fan control driver | Defective fan PCB Defective connection of capacity setting adaptor Field setting error |

V | V | ||||||

| C7 | Front panel driving motor fault | Defective front panel driving motor Defective limit switch |

V | |||||||

| C9 | Malfunction of suction air thermistor | Defective thermistor for suction air Defective indoor unit PCB Defective connector contact |

V | V | V | V | V | V | ||

| CA | Malfunction of discharge air thermistor | Defective thermistor for discharge air Defective indoor unit PCB Defective connector contact |

V | V | V | V | ||||

| CC | Malfunction of humidity sensor system | Defective humidity sensor Defective connector contact |

V | V | V | |||||

| CJ | Room temperature thermistor in remote controller abnormality | Defective room temperature thermistor in remote controller Defective remote controller PCB External factor (Noise etc.) |

V | V | V | V | V | |||

| H5 | Malfunction of compressor motor overload thermistor | Defect of compressor motor overload thermistor Defective connector contact |

V | V | ||||||

| H6 | Malfunction of position detection sensor | Faulty contact of compress or cable Defective compressor Defective outdoor unit PCB |

V | V | V | |||||

| H7 | Malfunction of outdoor unit fan motor signal | Abnormal signal from fan motor (Circuit failure) Disconnection/Short circuit in fan motor leads or disconnection of connector Defective inverter PCB |

V | V | V | V | ||||

| H8 | Malfunction of compressor input(CT) system | Defective power transistor Defective reactor Faulty wiring of inverter system Defective outdoor unit PCB |

V | V | ||||||

| H9 | Malfunction of outdoor air thermistor | Defective connection of thermistor Defective outdoor unit PCB Defective outdoor air thermistor |

V | V | V | V | V | |||

| HC | Malfunction of (hot) water temperature thermistor | Defective connection of thermistor Defective outdoor unit PCB Defective water temperature thermistor |

V | V | V | |||||

| HF | Alarm in thermal storage unit or storage controller | Thermal storage group defective wiring Defective setting Excess of thermal storage tank numbers |

V | |||||||

| HJ | Malfunction of thermal storage tank water level | Low water level Defective switch setting Water level detecting sensor failure Defective connector contact |

V | V | V | V | ||||

| J1 | Malfunction of pressure sensor | Defective pressure sensor connector contact Defective pressure sensor Defective outdoor unit PCB |

V | V | V | V | ||||

| J2 | Malfunction of current sensor of compressor | Defective current sensor Defective compressor Defective outdoor unit PCB |

V | V | V | V | V | |||

| J3 | Malfunction of discharge pipe thermistor | Defective connection of thermistor Defective discharge pipe thermistor Defective outdoor unit PCB |

V | V | V | V | V | |||

| J4 | Malfunction of low pressure equivalent saturated temperature sensor system |

Defective connection of thermistor Defective thermistor Defective outdoor unit PCB |

V | V | ||||||

| J5 | Malfunction of suction pipe thermistor | Defective connection of thermistor Defective suction pipe thermistor Defective outdoor unit PCB |

V | V | V | V | ||||

| J6 | Malfunction of heat exchanger thermistor | |||||||||

| J7 | Malfunction of thermistor (Refrigerant circuit) | Defective connection of thermistor Defective liquid pipe thermistor Defective outdoor unit PCB |

V | V | V | V | ||||

| J8 | Malfunction of thermistor (Refrigerant circuit) | Defective connection of thermistor Defective liquid pipe thermistor Defective outdoor unit PCB |

V | V | V | V | V | |||

| J9 | Malfunction of thermistor (Refrigerant circuit) | Defective connection of thermistor Defective gas pipe thermistor Defective outdoor unit PCB |

V | V | V | V | V | |||

| JA | Malfunction of high pressure sensor | Defective connector contact Connection of low pressure sensor in mistake for high pressure sensor Defective high pressure sensor Defective outdoor unit PCB |

V | V | V | V | ||||

| JC | Malfunction of low pressure sensor | Defective connector contact Connection of high pressure sensor in mistake for low pressure sensor Defective low pressure sensor Defective outdoor unit PCB |

V | V | V | V | ||||

| P2 | Automatic refrigerant charge operation stop | The stop valve is not opened Closed valve of refrigerant tank |

V | V | V | V | ||||

| P3 | Malfunction of thermistor in switch box |

Defective connection of thermistor Defective reactor thermistor Defective inverter PCB |

V | V | V | V | V | |||

| P4 | Malfunction of radiation fi n temperature sensor |

Defective radiation fi n temperature thermistor Defective inverter PCB Defective INV. compressor Defective fan motor |

V | V | V | V | V | |||

| P8 | Heat exchanger freezing protection during automatic refrigerant charging |

|||||||||

| P9 | Malfunction of fan motor (humidifi er unit) |

|||||||||

| P9 | Automatic refrigerant charge operation completed |

— | V | V | V | V | ||||

| PA | Refrigerant cylinder during automatic refrigerant charging |

Refrigerant cylinder of master unit is empty | V | V | V | |||||

| PA | Broken wire of heater (humidifi er unit) |

Defective heater unit Defective thermistor Defective outdoor unit PCB |

V | |||||||

| PC | Refrigerant cylinder during automatic refrigerant charging |

Refrigerant cylinder of slave unit 2 is empty | V | V | ||||||

| PE | Automatic refrigerant charge operation nearly completed |

— | V | V | V | |||||

| PH | Refrigerant cylinder during automatic refrigerant charging |

Defective heater unit Defective connector contact Defective thermistor Defective outdoor unit PCB |

V | V | V | |||||

| PJ | Malfunction of capacity setting (Outdoor unit PCB) |

Capacity setting adaptor is not installed Improper capacity setting adaptor Defective outdoor unit PCB |

V | |||||||

| PJ | Improper combination between inverter and fan driver |

Mis-matching of type of PCB Improper (or no) fi eld setting after replacing outdoor unit main PCB |

V | V | V | V | ||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||

| AJ | ||||||||||